When it comes to corrugated packaging, the strength of the box is a crucial factor in ensuring that the contents inside are well protected during shipping and handling. To measure box strength, two standard tests are commonly used: the Edge Crush Test (ECT) and the Mullen Burst Test. Both tests aim to evaluate the strength and durability of corrugated boxes but differ in their testing methods, as they target different material properties.

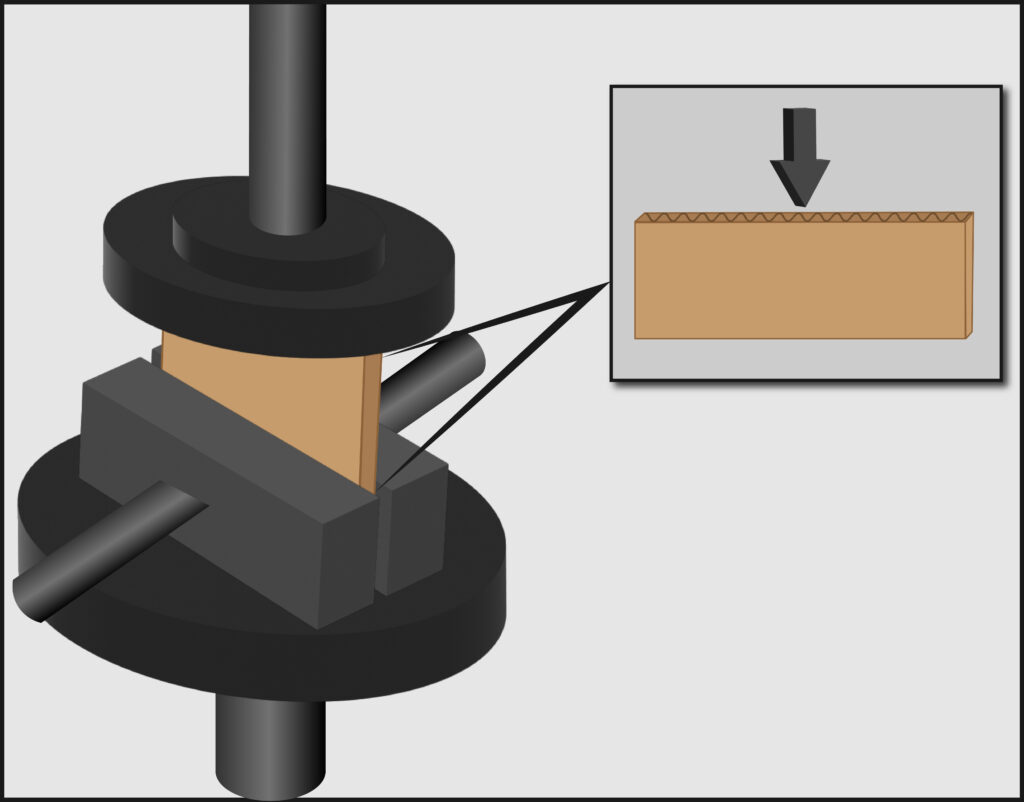

Mullen Burst Test

The Mullen Test, also referred to as the Mullen Burst Test or Burst Strength Test, is a standard test used to evaluate corrugated board’s resistance to puncturing or bursting. It measures the amount of force, in pounds per square inch (PSI), required to rupture the face of the board using pressure and a Mullen tester. The final results are reported in pounds (#). This test assesses how the board reacts when subject to rough handling, indirectly related to the box’s ability to withstand both internal and external forces and how effectively it can protect and contain its contents during handling and transportation.

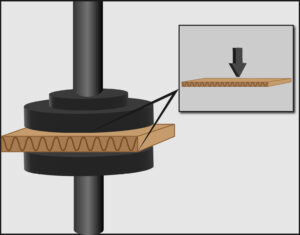

Edge Crush Test

The Edge Crush Test (ECT), also known as the Short Column Test, is directly related to the stacking strength of a corrugated box. This test evaluates the edgewise compressive strength of corrugated board in pounds per inch of width, with the results communicated as an ECT value (ex., 32 ECT rather than as 32 lbs./in.). During the test, the flutes are oriented vertically and the amount of force the edge can withstand, from top to bottom, is reported. The ECT value is a crucial factor in estimating the compression strength of a box, as it has the largest influence and is directly proportional to the compression performance, allowing for a reliable estimation of compression strength from the ECT value and vice versa.

Differences

The Mullen Test was the first test used in the industry. However, the Edge Crush Test has become the more popular way to evaluate corrugated board strength. Today, box manufacturers can create high strength board using significantly less fiber, providing a stacking strength comparable to Mullen grade board. Less fiber is required for ECT grade boards when compared to Mullen grade boards because Mullen values are directly related to the combined weight of the individual facings comprising the board.

Recommended Mullen and ECT Values based on Weight of Box and Contents and Board Type

| Maximum Weight of Box and Contents (lbs.) | Minimum Edge Crush Test (ECT) (lbs. per inch width) | Minimum Bursting Test (psi) |

| Single Wall Corrugated Fiberboard Boxes | ||

| 20 | 23 | 125 |

| 35 | 26 | 150 |

| 50 | 29 | 175 |

| 65 | 32 | 200 |

| 80 | 40 | 250 |

| 95 | 44 | 275 |

| Double Wall Corrugated Fiberboard Boxes | ||

| 80 | 42 | 200 |

| 100 | 48 | 275 |

| 120 | 51 | 350 |

| 140 | 61 | 400 |

| 160 | 71 | 500 |

| 180 | 82 | 600 |

Key Differences Between the Two Boards:

- Testing Method: The obvious differentiator is how the two boards are tested, using the Edge Crush Test or Mullen Burst Test.

- Strength: ECT boards are identified by their vertical compressive strength along the edge of the board, in pounds per inch of width (reported as ECT). Mullen boards are identified by their bursting or puncturing strength, in pounds per square inch (reported in pounds).

- Uses: Mullen Boards are typically preferred when shipping heavy products, oddly shaped products, products with sharp features, or products that are bound to encounter severe handling. ECT boards are typically used for products that are palletized and/or stacked when shipped or in warehouses.

- Cost: ECT grade boards are usually less costly than Mullen grade boards as they require less material.

If you want high-quality and sustainable corrugated packaging solutions that meet your unique business requirements, contact Advanced Packaging today and experience the difference in our unparalleled service and expertise. With our custom packaging capabilities and corrugated stock packaging available, we are sure that we have right box style and strength that your product requires!

Source: Fibre Box Handbook, 75th Anniversary Edition