Establishing Packaging Specifications Puts an End to Inefficient Packaging Line

Our team at Advanced Packaging was approached by a fertilizer company to help them determine the problem with their pallets. Specifically, our customer was having issues with used pallets not working consistently on their packaging line, causing the line to frequently shut down. The faulty pallets were considered unusable – resulting in waste, money lost, and delayed shipments. With the growth of their business, it was crucial that we came in and resolved the problem as quickly as possible and put an end to their inefficient packaging line.

Current Packaging

- On average, 48″ x 40″ grade A used pallets

- 1″ x 4″ lead edge boards

- No technical specifications for the pallets other than the sizing stated above

- Basically, the company received grade A pallets that were in stock with little to no specifications

How We Helped

After meeting with the fertilizer company and observing their packaging line, we learned they had no pallet specifications with which the vendor was held accountable to. We asked the questions to determine what the specifications needed to be and then created a drawing to illustrate the required specs. Following the establishment of the specifications, we partnered with a pallet company and helped them build a system to maintain the specifications for the pallets.

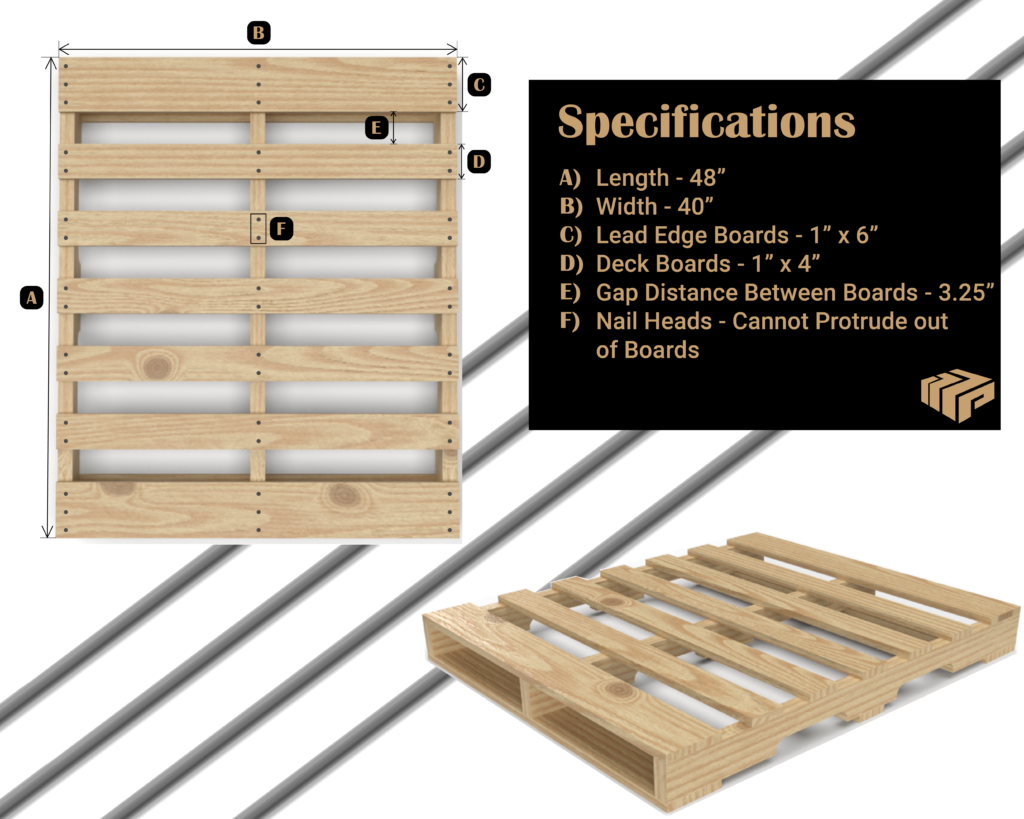

New Packaging Solution

Keeping cost and sustainability in mind, we were able to come up with a solution that allowed the customer to continue using refurbished/used pallets but with allowed customization to meet necessary specifications.

- Stringer Style Pallet – Grade A

- Pallets not wider or longer than specific tolerance

- 48″ x 40″ pallets with +/- ¼” tolerance

- No gaps beyond certain dimensions between deck boards

- 3 ¼” with +/- ¼” tolerance

- 1″ x 6″ top and bottom lead edge boards

- 1″ x 4″ top and bottom deck boards

- No nail heads protruding out of boards

Outcome

The business was won by evaluating the problem through a technical eye and ultimately providing pallets that would not shut down their packaging line.

The new pallets led to:

- Increased production efficiency

- Increased output

- Improved customer satisfaction

- Less waste = improved sustainability

- Cost savings

- Shorter shipping time

- Valuable insight on the importance of packaging specifications

To avoid faulty and inconsistent packaging which can result in shut down lines, it is essential to establish and maintain specifications for every aspect of your packaging.