-

Air Cushioning12 Products

-

Anti-Static Bubble Rolls - Perforated7 Products

-

Bottle Shippers30 Products

-

Bubble Dispensers14 Products

-

Bubble Pouches75 Products

-

Bubble Products1 Product

-

Bubble Rolls - Adhesive2 Products

-

Bubble Rolls - Cohesive2 Products

-

Bubble Rolls - Perforated44 Products

-

Cellulose Wadding7 Products

-

Cloud Foam19 Products

-

Compostable Foam2 Products

-

Convoluted Foam7 Products

-

Cushioning Pads6 Products

-

Foam Corners5 Products

-

Foam Dispensers8 Products

-

Foam in a Bag16 Products

-

Foam Pouches24 Products

-

Foam Products1 Product

-

Foam Rolls81 Products

-

Foam Sheets8 Products

-

Haz Mat Foam10 Products

-

Kraft Paper1 Product

-

Loose Fill11 Products

-

Newsprint Rolls8 Products

-

Newsprint Sheets25 Products

-

Parcel Ready Bubble Rolls18 Products

-

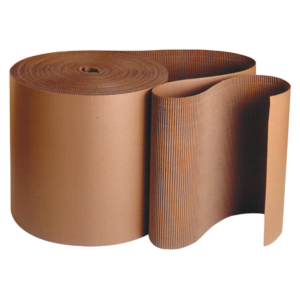

Single Face20 Products

-

Vermiculite4 Products

The primary purpose of packaging is to protect your goods from damage during every stage of the delivery process. Polyethylene, foam, and paper are protective packaging materials commonly used for void-fill and light cushioning applications. In addition to protection, each of these materials have beneficial advantages such as barrier properties and recyclability.

Material choice, size, and thickness are all factors to consider when choosing your protective materials. Our team of packaging engineers can help you make this choice to ensure you are packaging your products with the optimal amount of material to eliminate waste and ultimately reduce the risk of damaged goods.

Related: Corrugated Boxes, Kraft Paper