In the world of manufacturing and shipping, corrosion is a silent yet costly enemy. According to studies, corrosion damage costs industries worldwide billions of dollars annually. Whether it’s rust on metal parts, tarnishing of electronics, or the degradation of machinery, the impact of corrosion is both extensive and expensive.

This is where VCI (Volatile Corrosion Inhibitor) packaging comes into play. Designed to combat the effects of corrosion, rust, and oxidation, VCI packaging offers a proactive solution for protecting products during storage and transit.

What is VCI Packaging?

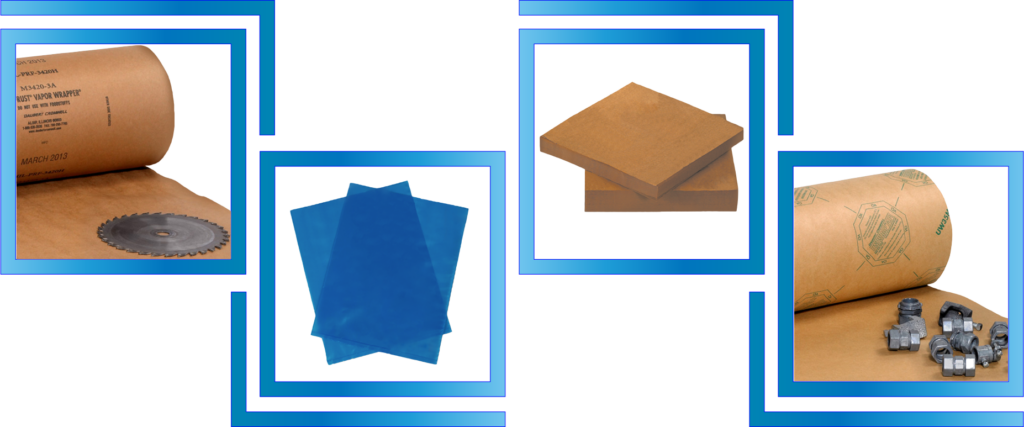

VCI (Volatile Corrosion Inhibitor) packaging is a specialized type of protective packaging designed to prevent corrosion on metal surfaces. The key to its effectiveness lies in the chemicals that are embedded within the packaging material. These chemicals gradually release vapor molecules that settle on the surface of the metal, creating an invisible protective layer that inhibits the electrochemical reactions responsible for corrosion.

Corrosion is the slow deterioration of materials, most commonly metals, due to chemical reactions with their surrounding environment. This process often involves metals reacting with substances like oxygen or water, leading to the formation of oxides or other compounds on the metal’s surface. A typical example is rust, which forms when iron reacts with oxygen and moisture, resulting in iron oxide. Corrosion can weaken materials, reduce structural integrity, and cause costly damage in various industries.

VCI packaging comes in various forms, including films, papers, bags, sheets, and stretch wraps, each tailored to specific needs and applications. These materials are used to wrap or encase products, ensuring that they are shielded from moisture, oxygen, and other contaminants that contribute to corrosion.

Benefits of VCI Packaging

The primary benefit of VCI packaging is its ability to protect products from corrosion, ensuring they remain in excellent condition until they are needed. Additional benefits include:

- Cost-Effectiveness: Reduces losses from corrosion-related damage, returns, and recalls.

- Easy Application: Simple to use in various forms like films, papers, and bags.

- Waste Reduction: Helps eliminate product and packaging waste, contributing to sustainability efforts.

- Long-Term Durability: Provides continuous protection during storage and transit.

Common Use Cases

Industries across the globe rely on VCI packaging to protect valuable products from corrosion during shipping, storage, and even long-term warehousing. Some common use cases include:

- Automotive Industry: Protecting metal parts such as engine components, gears, and fasteners during storage and shipment.

- Electronics: Shielding sensitive electronic components like circuit boards and connectors from corrosion.

- Military and Defense: Preserving metal tools, machinery, and weapons in harsh environmental conditions.

- Manufacturing: Protecting machinery and tools during storage or transport to maintain quality and efficiency.

Choosing the Right VCI Packaging

Consider the following factors when choosing VCI solutions:

- Product Type: Match the packaging to the specific needs of your product.

- Storage Duration: Determine the required protection based on how long the product will be stored or in transit.

- Environmental Conditions: Choose packaging that offers adequate protection against humidity and temperature.

- Consulting with Experts: Seek advice from packaging specialists to select the most effective solution tailored to your needs.

Volatile Corrosion Inhibitor packaging stands as a vital solution for combating corrosion and preserving the quality of metal products across various industries. By understanding its benefits and selecting the appropriate packaging, businesses can effectively protect their investments and ensure their products remain in excellent condition, ultimately saving costs and reducing waste.

Let’s talk about protecting your products from costly corrosion.